Make Your Own Recording Studio Acoustic Panels

Kimera MorrellDIY acoustic fixtures for around $200. Compare to Auralex $650.

I feel very proud of my home made fiberglass foam acoustic panels that help absorb sound just right for optimal vocal recording! Read below about how I made my panels, and if you're like... nahhhh that's too much, I can recommend purchasing this set by Primacoustic as a backup plan: https://shorturl.at/nTDHM

Before we get started, here's a link to my curated list of studio gear all on Amazon: https://www.amazon.com/shop/kimeramorrell

Supplies you’ll need:

*prices will vary slightly based on which exact fabric you choose, and how many panels you make. Below is based on four 2x4 ft panels.

- $80 Owen’s Corning 703 Insulation Panels (2x4’ panels, 2” thick)

- $50 Fabric

- $6 Work Gloves

- $10 Scissors

- $11 Spray Glue

- $4 Upholstery Finishing Tacks

- $40 Surface Impalers —> https://shorturl.at/wz9HX

- $7 Screws

- $11 Tape Measure

Part 1: Getting everything you need

Step 1: Look up local insulation companies and phone them up and ask if they have Owens Corning 703 panels or a generic brand that they can sell you in a small amount of them. In my case, I found a generic kind and they would only sell me a minimum of 6 panels paid in cash. Sketchy haha, most likely because these companies mainly deal on a commercial level. I’ve seen prices range from $40-100 for a pack of 2 foot by 4 foot panels (2 inch thick). Go get your panels!

Step 2: Order your surface impalers online. I got mine from Sweetwater: https://www.sweetwater.com/store/detail/SurfaceImpP--primacoustic-surface-mount-impaler-24-pcs

Step 3: Measure out how much fabric you’ll need. You can honestly get whatever fabric you want, some people say burlap is the best for acoustics but I disagree and think they’re all just fine. I personally went with burgundy duck cloth (it matches my microphone AND headphones lol).

I’m terrible with math, and fabric stores make it more confusing by using “yards” and “inches” and “feet” instead of choosing one metric. Enjoy my painful thought process of how I figured out how much fabric I needed:

Step 4: While you’re at the fabric store, also pick up your Upholstery Tacks, a nice pair of Scissors.

Step 5: Head over to Home Depot for the rest of your supplies. You need work gloves because you do not want to handle insulation with your bare hands or let it touch your skin at all. Be careful to especially not touch your face while working on these! Gloves, spray glue, screws for the surface impalers, and a tape measure.

Part 2: Make the Panels

Step 6: Find an area to work, I prefer outside since there may be fumes from the spray glue, and insulation might end up floating in the air and you don’t want your cat inhaling it. You’ll need a pretty wide flat surface, and might want to put a blanket down so your fabric doesn’t get dirty.

Step 7: Here’s the fun part! Let's put em together :)

- Spread out the fabric

- Lay the Owen’s Corning 703 across the fabric

- Fold the longest way fabric across the panel so it ends approximately in the middle of what will be the back of the panel.

- Cut the fabric and fold it to meet in the middle of the back of the panel with a few inches of slack.

- Have your Upholstery tacks handy. Spray the glue between the overlapping pieces of fabric, and as you close/seal the fabric, pull it tight, pat it down, and stick a few upholstery tracks in to secure about 6 inches apart or as you see fit.

- Seal the top and bottom of the panel by folding the fabric in like a present. Make sure to be pulling tight as you seal with the spray glue and upholstery tacks.

- Smile! Looks good right? Repeat for all your panels.

Part 3: Hanging the panels

Step 8: You’re somewhat on your own for this part, but essentially decide where you want to hang your panels on the wall.

Using your tape measure, figure out where you’ll be screwing your surface impalers into the wall. The surface impalers are extremely sharp- I dropped one and it barley touched my leg and put a big gash in me. Please be more careful than me!

The pointy part of the surface impalers should point up. Measure exactly where on your panels you plan to impale them. I measured and cut tiny slits in the four spots of the fabric where the impalers will enter the panel. You can get away with two impalers per panel, but 4 will be more secure. Hold the panel slightly above so you can see and feel the tips of the impalers are in the right spot where those slits are, then...

IMPALE!

That’s it! Aren’t you so proud!? You just saved a lot of money, and also got to enjoy the satisfaction of making something really cool all on your own.

Are you pretty new to setting up your home studio? Need a FREE course on how to use Pro Tools? I made you one and it's on Youtube ;) Check it out!

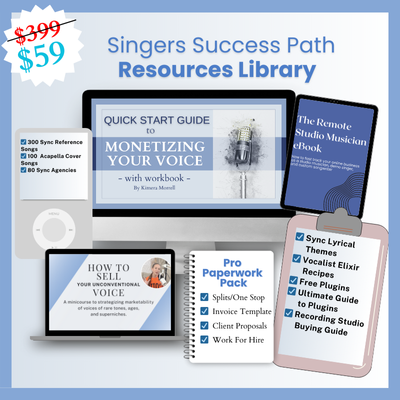

![Master List of Revenue Streams [FREE]](http://kimerav.com/cdn/shop/files/SSP_Resources_Square_1.png?v=1722012080&width=533)

![Vocal Recording Simplified Handbook [FREE]](http://kimerav.com/cdn/shop/files/SSP_Consulting.png?v=1722012447&width=533)